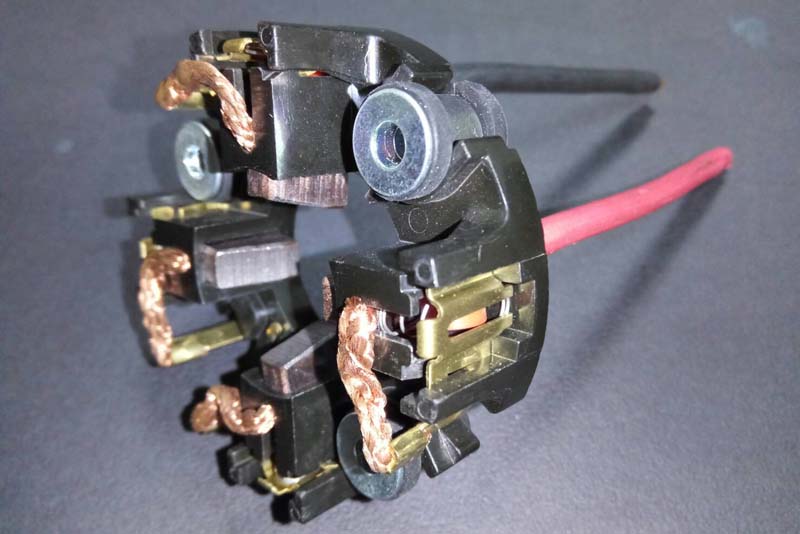

OTHER SVC

Various components welded and assembled into a motor core

End use:

Being an isolator/strut and or controller module for a car motor

Material:

isolation plastic pedestal/carbon brush pedestal/rubber rim/grommet/conductive copper terminal/wires/carbon brush/vibrator...

Feature:

Shear & strip cable end,press and weld bare wire ends to copper terminal, configure all components in order, press manually and or riveting terminal legs, onto the isolated plate by press machine, free of burr is the compulsory demand

Radiator cap

End Use:

For tapping the radiator

Material:

SUS 304 stainless steel+ sealed rubber pad+ interior/exterior gasket

Feature:

Tailor-made SUS metalwork+ waterproof rubber pad, 5 components assembled and welded into an unit; strict flatness and concentricity was the concern, no burrs or particls left permitted

Brackets and shaft

End Use:

Metal components applied on the power seat

Main material:

Steel+ Customized shaft+drum disc

Feature:

Material: Improper material will lead too much welding scraps(beads) and deforming, dimension variation; loss of reboundance control will cause rotation of the shaft unsmooth, as riveting the drum disc, should strictly control the width, wider or narrower will be inappropriate; plating thickness control/material of drum disc are also essential on its quality demand

Gear kit

End Usage:

Gear kit applied on a power window of a car and or brake of a sledge

Main material:

Tailor-made plastic gear/ metalwork/ rubber pad

Feature:

Subject to the work sheet, organize these parts in different material, promptly and corrrectly