PRODUCTION

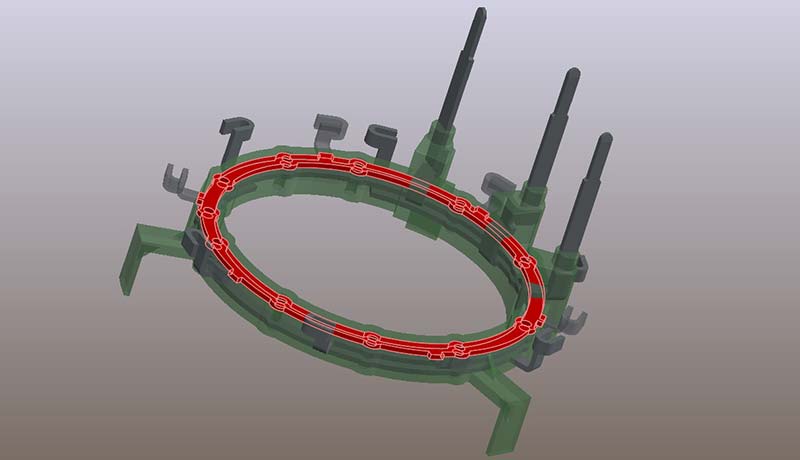

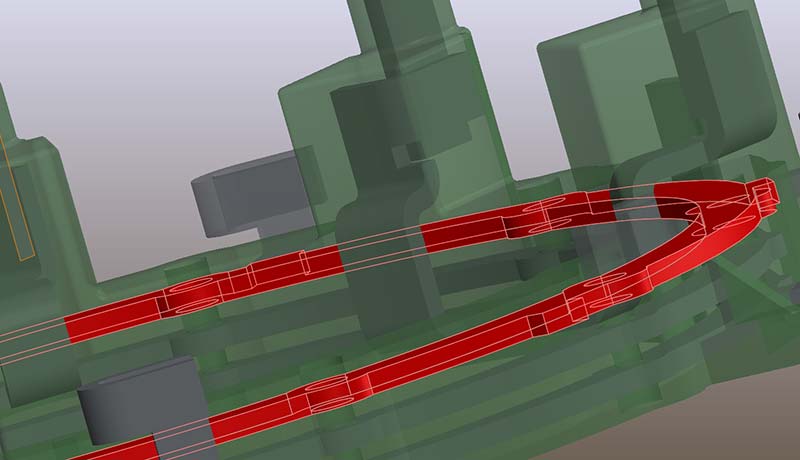

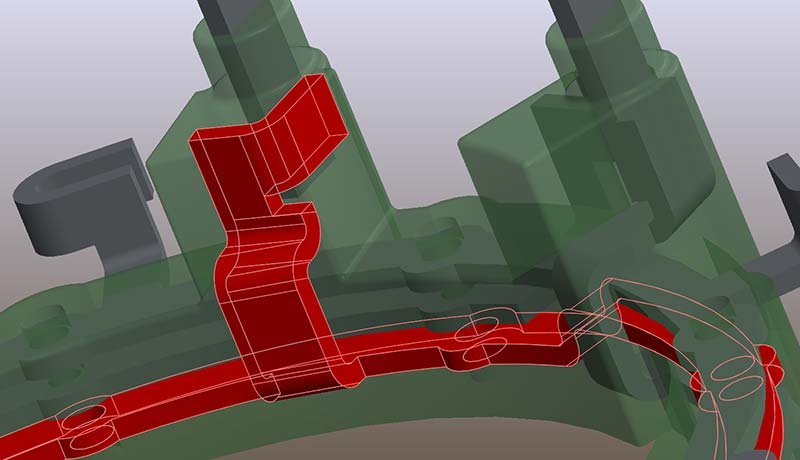

TOOL DESIGN & BUILD

Ming Pu's competent tool designer and maker building tools in-house; by the advanced technology and facility, we always develop out those high precision and complex tools for the OEM demand.

We accept your unique request to the tool life on the very first beginning, we understood however, as the new product is under conceiving, maybe you just need a simple and cheap temp. tool for the technical verification, cost too high will be absolutely your latest /unideal consideration.

We equipped with the advanced solidwork 3D software, meanwhile, CNC machining, wire EDM machines(this process used was in-house but now outsourced), grinding equipment, polishing M/C......etc.; The most, we immerse ourselves in the job 7 days a week when our customers have this kind critical requirement.

This is our criteria, we also support ongoing training, however, it’s all about for achieving the highest level of quality and efficiency. The tools we can offer include for progressive and or stage mold products manufacture.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

PUNCH & PRESS

We povide OEM metalwork, stamping and press product and its related service; starting from drawing studying and appraising, mold design, mold manufacture until the product finish and it's relevant process, including assembly/welding/soldering/riveting/cleansing/electroplating/electrodepositing/ anodizing/polishing/sand blasting/brushing/vibration deburring/hydrogen embrittlement disposal/ heat treatment/ passivation disposal/electrolyzing....etc.; can satisfy all your OE request to a metalwork

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

INSERT MOLDING

We produce the insert molding product in-house

We owned plastic injection machine on side, combine both the plastic injection and a metalwork into one unit; it's just part of the turn-key solution we can offer; in other words, 2 metalworks riveted together, welded together, overmold process, completely subject to your tailor-made requirement(OEM service)

-.jpg)

-.jpg)

.jpg)

ASSEMBLY SERVICE

The scope of the assembly service includes various kinds of components assembly; such as with plastic/ rubber/ silicone rubber/other metal material items but not limited………, moreover, built-in welding equipment, we can practice welding service and its related electricity detest after fabrication; riveting service via applicable stamping and press M/C for sure, too; you are welcome to address any of the request on any of the assembly service; the meanwhile, owing to the owned ultrasonic cleansing M/C and dryer, we also provide degreasing service in factory too

.jpg)

.jpg)

.jpg)

3D SOFTWARE

We adopt solidwork/autocad coordinated software as the 3D/2D dimensional communication over interior and exterior platform, all the related drawing format are acceptable, such as .stp./.igs/.dwg/.dxf......etc.