DEEP DRAWN

Clutch/bearing fixer applied on car motor

End use:

applied on a car motor

Material:

Steel + nitempering disposal + vibration grinding deburring

Feature:

Deep drawn the sheet steel plate, prevent from cleavage or scratch is the most concern,

burr residue/crimp or warpage is strictly refused;

final finish is vibration grinding deburring and nitrocarburizing; as well, fix the bearing is another concern

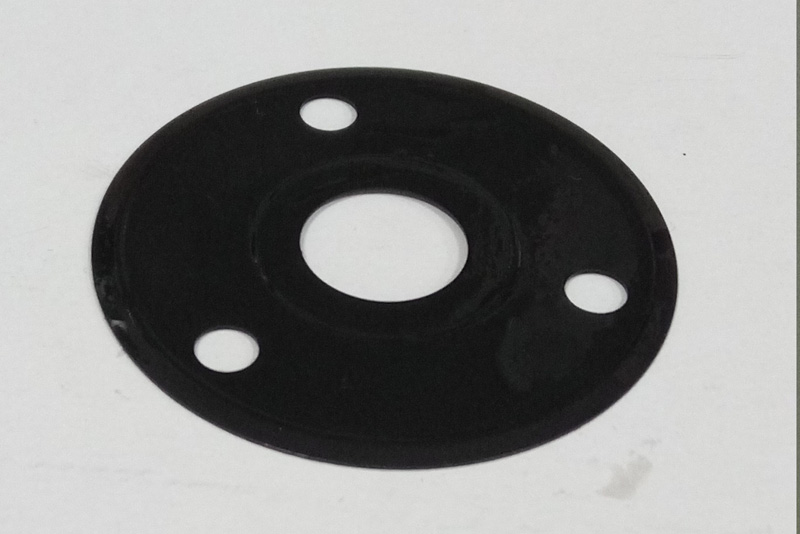

Magnetism shielding case

End use:

applied on a car motor for magnetism isolation

Material:

SECC steel, the issues are on the such small 3 counter embossments, the center is a 33.9mm dia. and deep drawn pit;

Feature:

Produced by progressive mold and process, entirely no burr residue after punching & pressing, save cost and time from vibration deburring process no leakage or scratch allowance

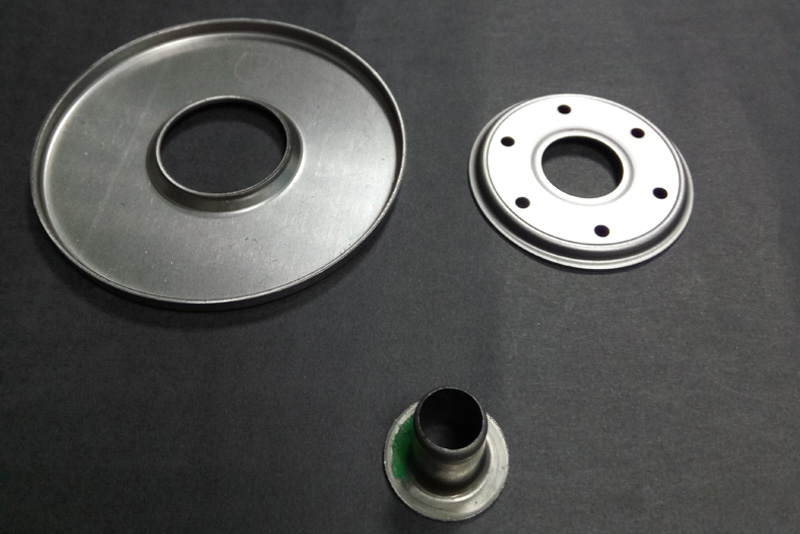

Magnetic core cover & protection boot

End use:

applied on a car motor

Material:

SUS304 stainless steel and or aluminum

Feature:

Finish by built-in ultrasonic cleanser; width of both rim are critical and they are requested in narrow dimension; we successfully have our products meet customer's demand

Deep drawn an aluminum sheet, have the soft and thin aluminum sheet be formed in a real-circle product and can accept nothing but about the burr and or defect on the product inner or outer side

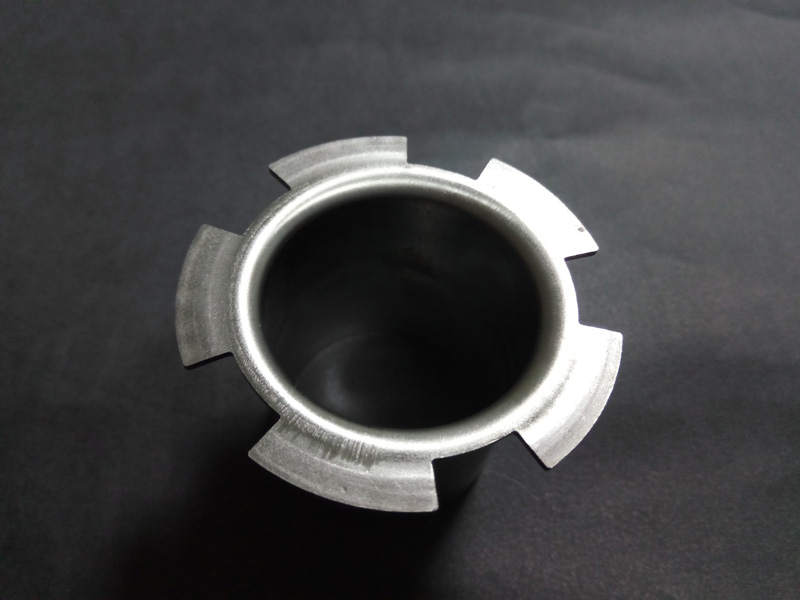

Toroidal base and the relevance

End use:

applied on a car motor

Material:

steel+ vibration grinding deburring+ electroplating

Feature:

Produced by progressive mold and process, prevent from blanking/mixture/colliding against the rod defect is the concern; product flatness is the critical demand, final disposal is electroplating to prevent from stain